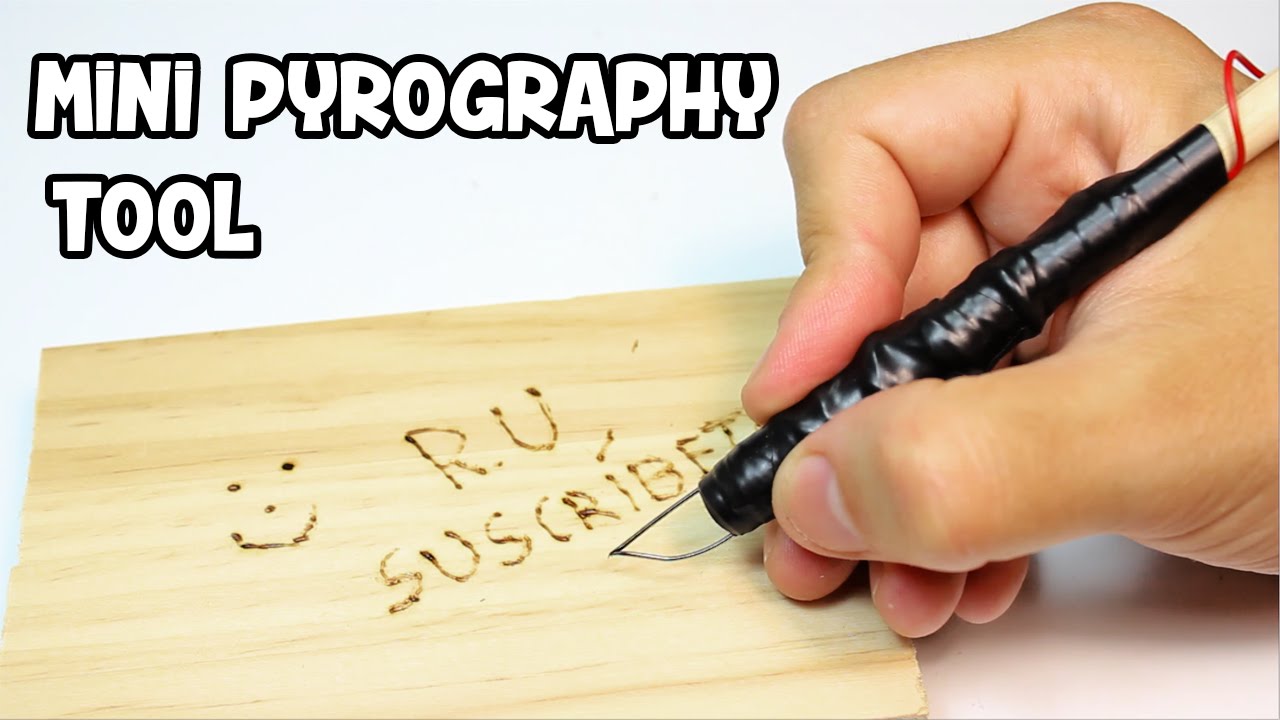

Make Your Own Wood Burning Tools

My 2017 branding iron is about to become obsolete.

Make your own wood burning tools. X2 RT Bushing without Tip Wire6 Straight Wire1 High Temp SolderIMPORTANT. Follow along as we show how to make your own. We used a dremel grinder to cut out a logo design into brass.

Of course that implies that we also need 20 years of practice with that perfect tool just like Gee Whiz has but that will not stop us from getting the tool. From there all you need to do is apply heat and you can burn your designs into wood leather or other suitable material. - Tungsten Carbide cutting bits - get a fine and regular size - A hacksaw or other metal cutting device - A vise to hold the workpiece - A sharpie and a pencil or carbon transfer paper - Safety gear - earplugs or headphones safety glasses - Some sort of welding gear to attach the handle to the brand or a high temp bonding agent of some sort First thing to do is make up your design - Some things to know - A design.

Ad Find Deals on Products in Power Tools on Amazon. When making your own tip the tip must be soldered into the RT Bushing. Insert the other end in the other tube.

Do this in several places around the fish and note the locations onthe paper. In response to the many comments and questions I received on this project I have done anot. Metal 3D prints are not cheap but youll have the brand forever and can stamp til you hearts content.

The logo was then mou. Screw in the two barrier strip tube screws to hold the nichrome tip in place. Insert one end of the 16 gauge nichrome tip wire into one of the barrier strip tubes at the end of the pen tube.

When soldering the Tip Wir. Once frozen remove it fromthe freezer and place a piece of white wax paper wax side down on the skinsurface and lightly rub the surface with a soft pencil to highlight the scaleoutlines. Wood turners are tool junkies There is the dream that given the perfect tool we will make the prefect cut.