How To Setup A Parting Tool On A Lathe

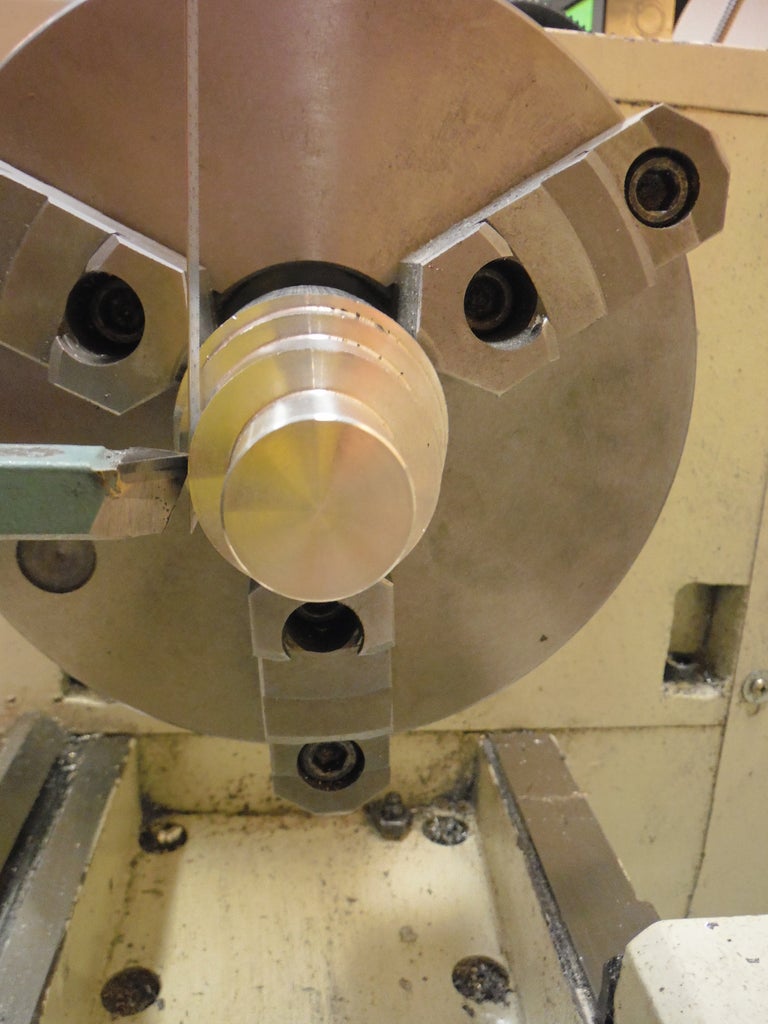

I took a practice cut on some 1 diameter aluminum rod.

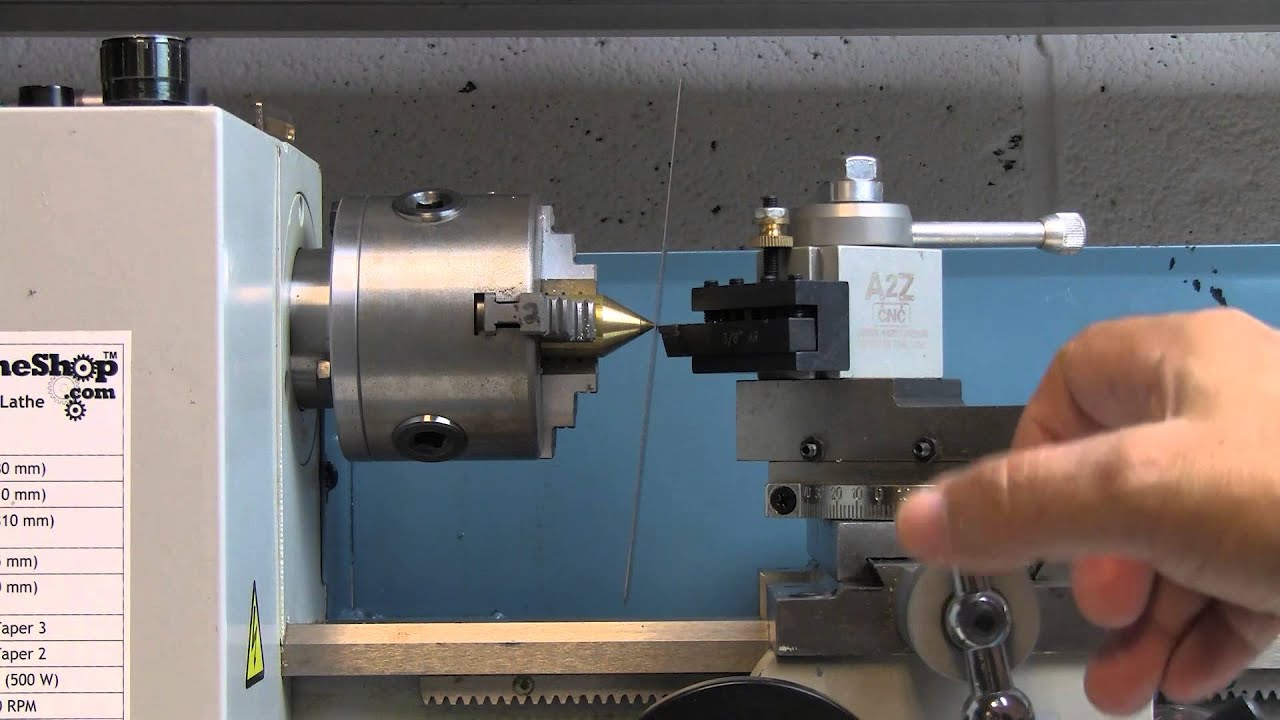

How to setup a parting tool on a lathe. With the tip of the tool just beyond the surface of the workpiece turn on the lathe. Parting is done with a special tool. First setting proper tool height will minimize the nib.

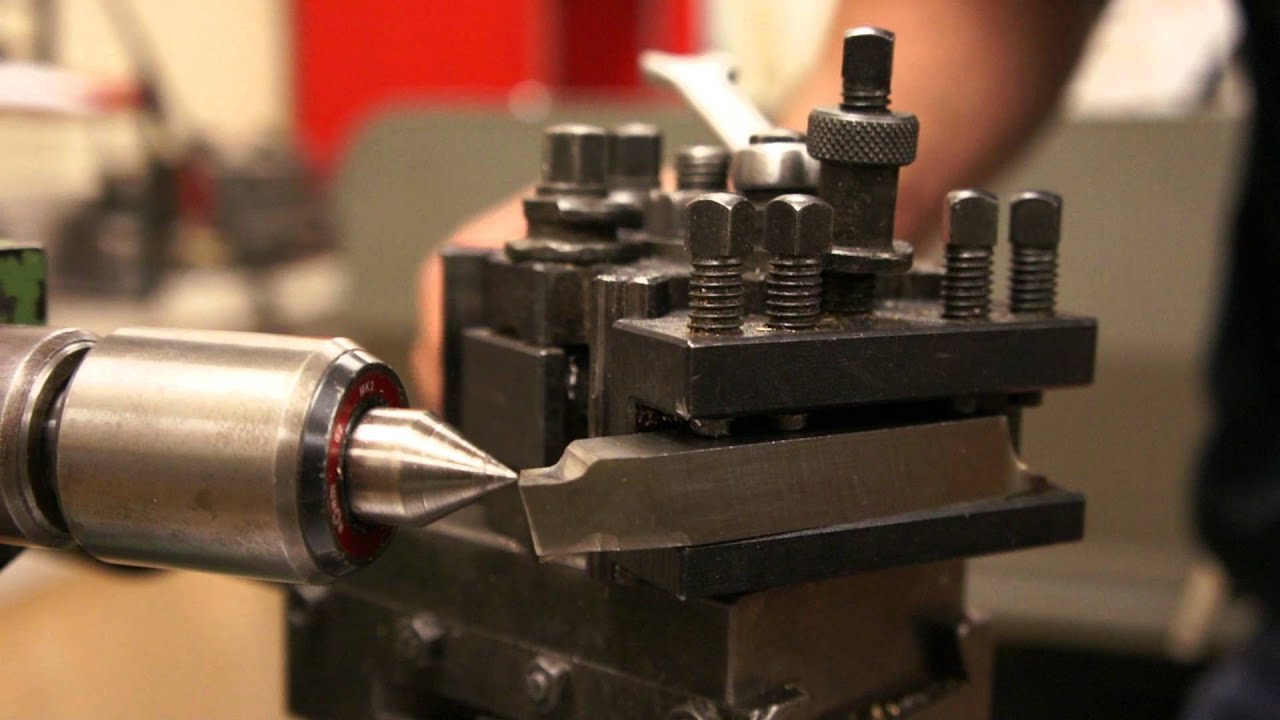

Be sure your parting tool is on center I like to use a 6 scale and trap it between the work and parting tool---when it is straight up--you are good to go. Turn the outside of the bowl to your desired shape. Next I took the blade over to the disk sander and ground it down to bare metal.

Double Angle Sorby Thin Parting Tool. Make sure it is the tool that you intend to use for your first cut. Second if the tip of the parting tool is ground at an angle it will minimize the nib further.

We recommend to use a sub-spindle if available. Load your cylindrical part in the chuck of a lathe when you tighten the chuck rotate the part with your hand lightly until it cant move anymore to center the turning part. Edges faceedge need to be 90 so must be held square to wheel.

Like all tools used on the lathe the part-off tool height must be checked and adjusted so it is as close to the vertical spindle centerline as possible. Not a very good shot but it does show the thickness. Then turn the workpiece round and face it to the right length.

I shaped the end of the blade like the Sorby Parting Tool double angle look. 2 x 22mm Parting inserts. Feed by hand and slowly at first--you will develop a feel for feed rate 4.