How Much Does It Cost To Start A Cnc Machine Shop

If not you will have to re-evaluate these expenses.

How much does it cost to start a cnc machine shop. It is common for someone to start-up with one manual milling machine so they can build capital for more machines such as a lathe horizontal bandsaw vertical bandsaw surface grinding machines etc. Starting out small with a few manual machines may be the only path for those who do not have all the money and client base to open a full service machine shop. Converted to a percentage for example this will come to something like 120 percent basically adding 20 percent profit to the cost.

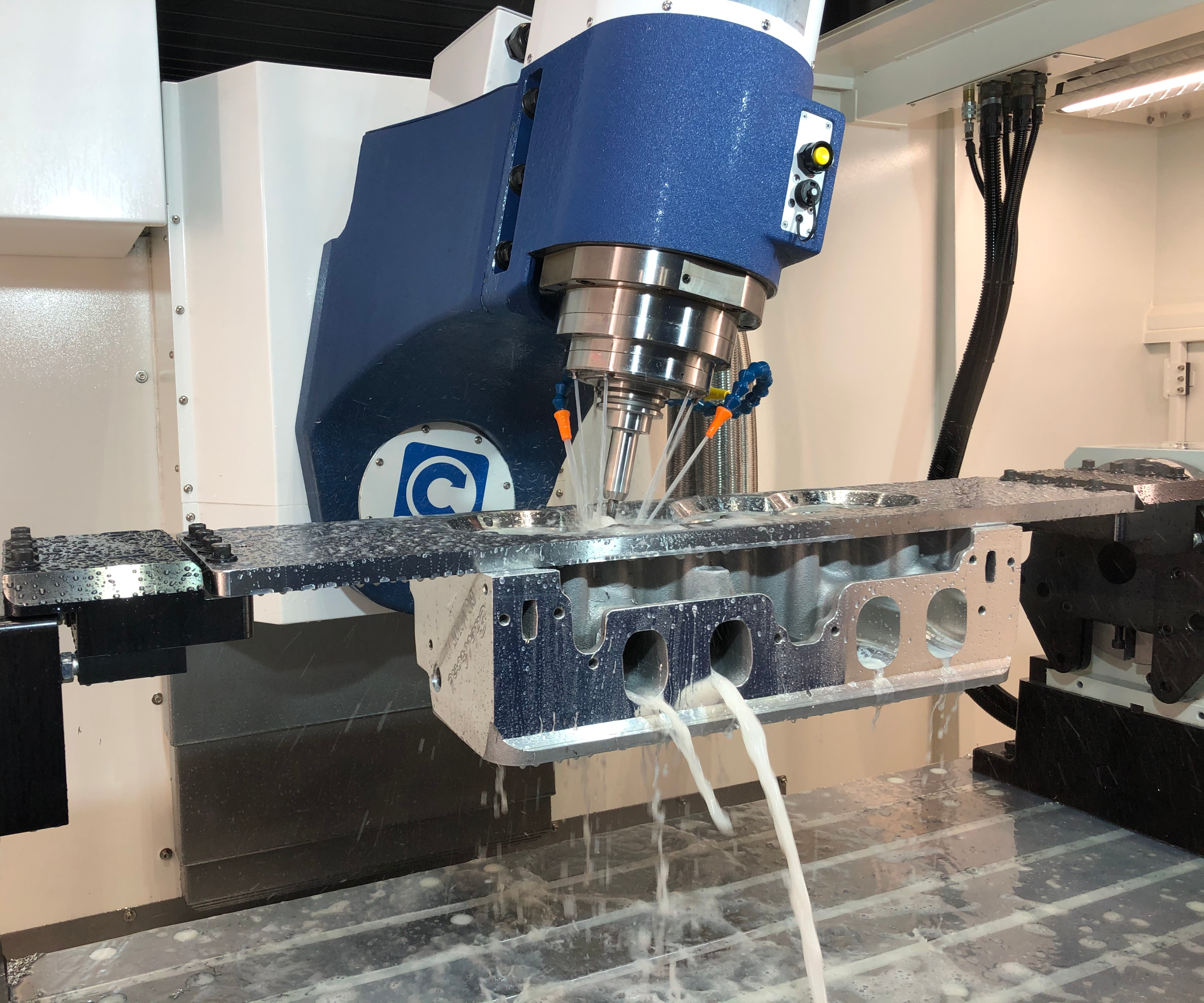

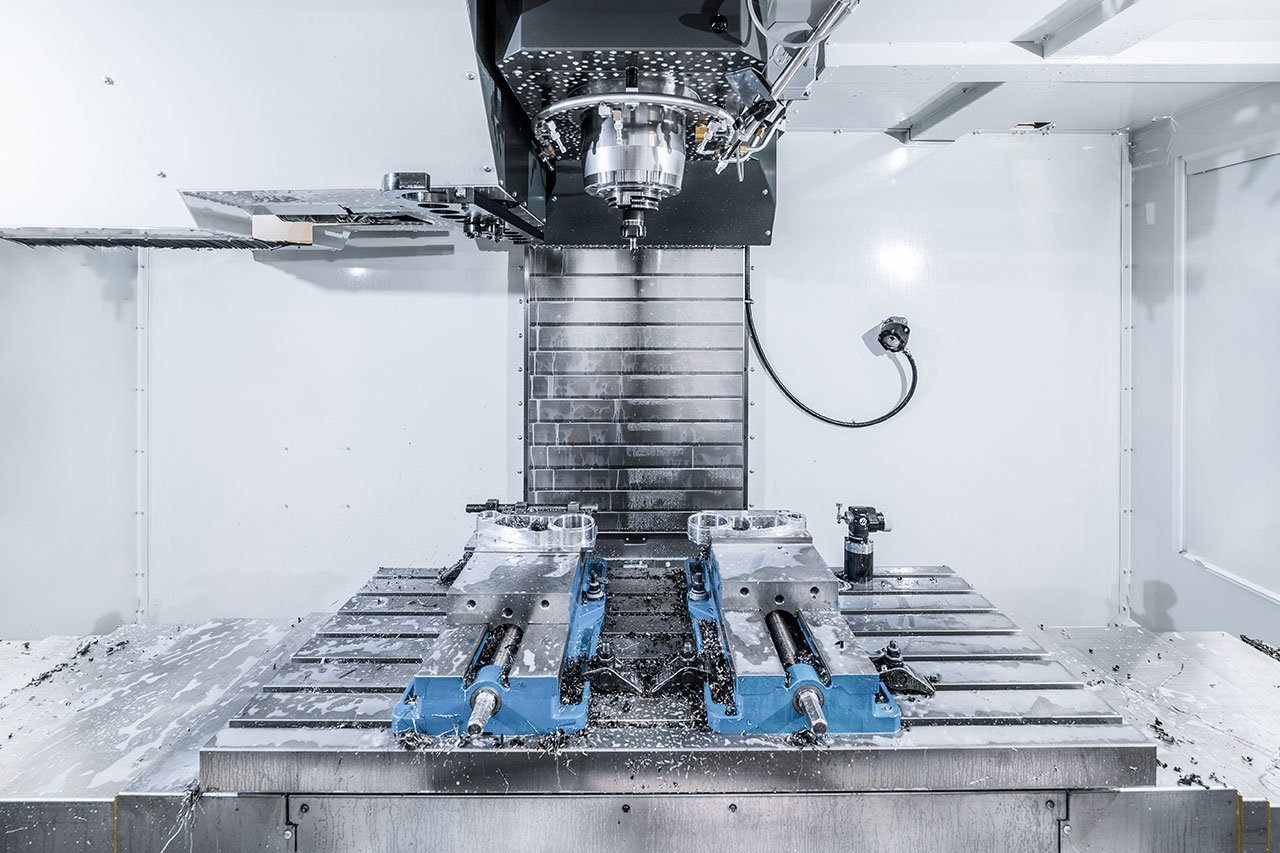

Multi-axis machines are more expensive to run so will cost more. When setting up any machine shop having a tight budget is almost always a concern. Haas is actually a really popular machine tool builder in the US that has a good lineup of entry-level machines.

You can find the Machine Hourly Rate Calculator on the Machine Profile under the Setup Basics tab. The price for CNC milling machines often increases to accommodate the operators salary as well. Until you start looking into it you might not realize just how cost-effective and strategically savvy it can be to buy second-hand equipment rather than automatically opting for a brand new model.

Videos you watch may be added to the TVs watch history and influence TV recommendations. If playback doesnt begin shortly try restarting your device. 3-axis machines including CNC milling machines which cost around 40 per hour to run and CNC turning machines which cost about 35 per hour to run.

For another 8-10K and youd be on your way. On the other hand there is a boatload of competition for the single-mill shop right now. Press the Calculate button to figure out the machines hourly rate.

Either buy your mill new or carefully test a. Profit in this kind of business is generally 10 to 20 of turnover or 100000 to 200000. We had to put in a whole new electrical panel and wiring to run to the machines.