How To Make Cnc Wood Router

All you have to do is type your code in plain text and save the file with the right extension nc orgcode.

How to make cnc wood router. It allows you to cut exact designs out of your material quickly. You decide about the order and number of. You can create a CNC program in any text editing application.

Attach with glue and screws. Prepare some thin hard metal sheet around 2mm thick to make bottle opener. Attach the Base End Panels with wood screws Figure 8.

The last type of CNC machine is certainly the most common one that you will see. You can make this a source of side income or even make it your full-time job it is a high-paying job. Find some things that are selling in your area and make your own version of them.

The Torsion Base core is centered on the Base Front and Rear panels. Keep the Torsion Base core face-down on the flat surface while attaching the front and back. You get to watch all the work coming to life the blank piece of wood transforming into the desired object.

The design also comes with a customizable top which can be decorated with any emblem or design you deem fit. The first step to take before you can earn from selling CNC router projects is to know how to use the technology efficiently. Kinetic sculpture - This amazing CNC sculpture will make it look good on your wall.

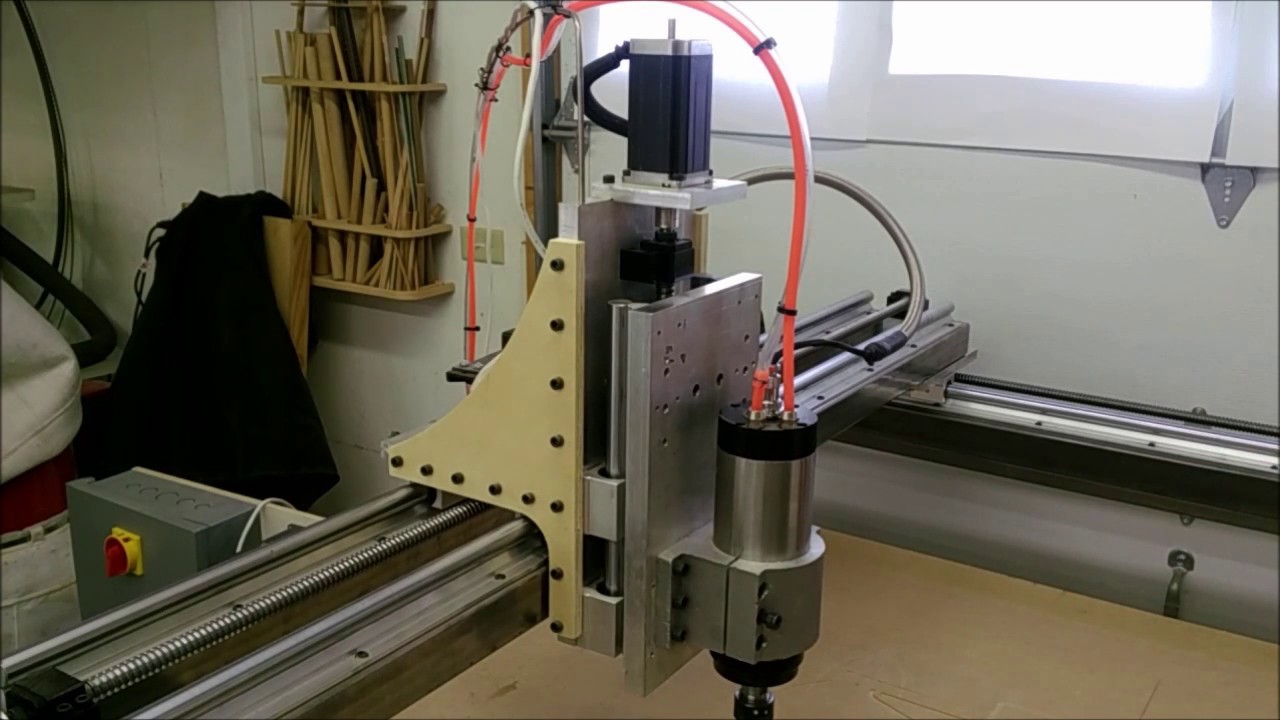

Milling furniture woodworking instrument design and decorative hardware production are just some of the ways to make money using a CNC router. For homemade CNC routers drive screws are most commonly used. CNC wood routers make the production of different types of furniture such as cabinet boxes and lounges very simple.