How To Make A Parting Tool Holder

Successful chip control Cutting tools featuring over- and under-coolant delivered with high precision means you can control both chips and temperature for highly productive and problem-free parting and grooving.

How to make a parting tool holder. If superior tool edge sharpness is not necessary choose a 3-edge or 2-edge insert for a more economical solution or for larger diameters. Fig cranked parting tool holder. C any other designs that basically does the same thing like parting from the opposite side of the spindleetc.

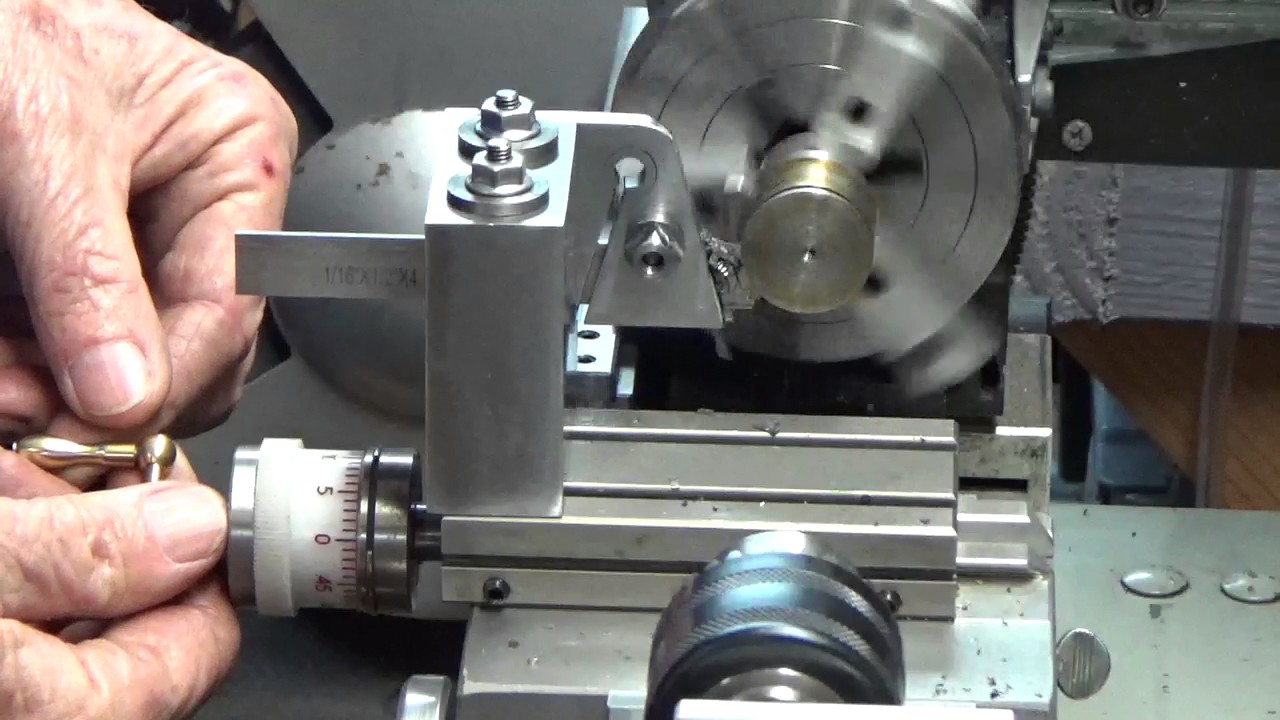

Even better if you have made a carriage lock use it. For 1 long try the front wedge for a sliding fit. Parting cuts should be made at low speed.

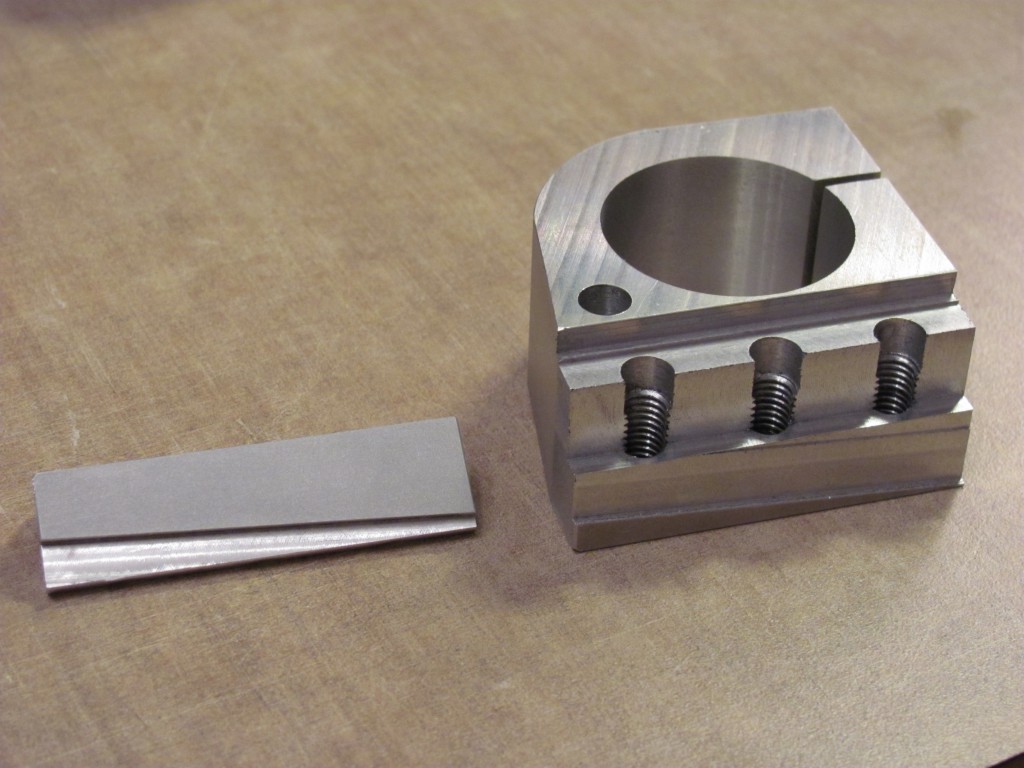

Use a master square to set the tool holder square with the lathe chuck and tighten the nut to lock the tool holder in place. For best process security use a tool with precision coolant. This is two parts.

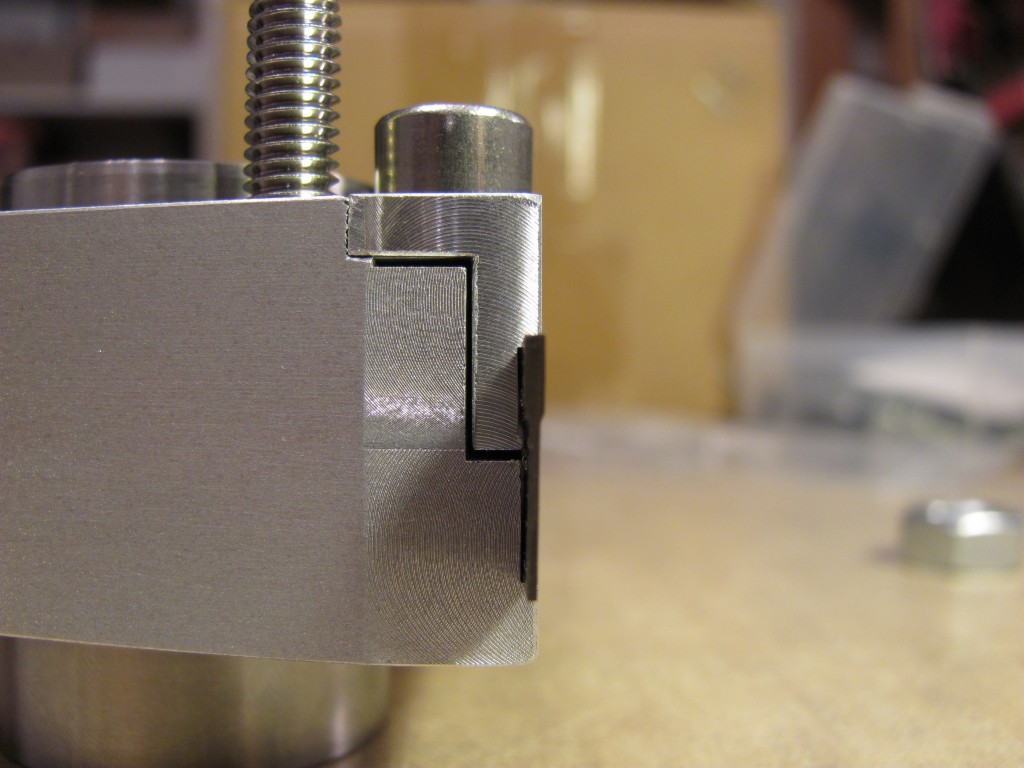

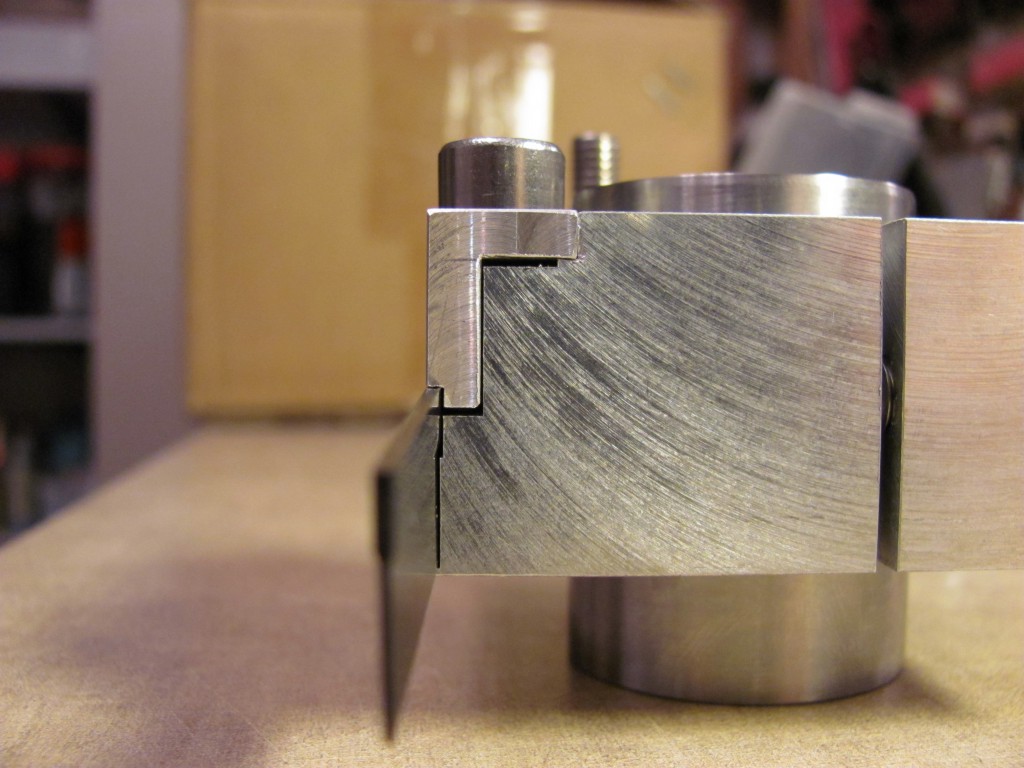

Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting. Turn round in chuck and repeat for side wedge hole. Back view showing how its mounted to the tool holder.

Rigidity is extremely important. All parting has to be done with the cutter at right angles to the workpiece. The only way this happens is when the lathe is fitted with an American style toolpost.

Not sure of type. I had a short production run I needed to finish and part of the process required a small groove at the end of the piece. Facingturning holder but holds the parting blade inverted.