How To Build Your Own Cnc Wood Router

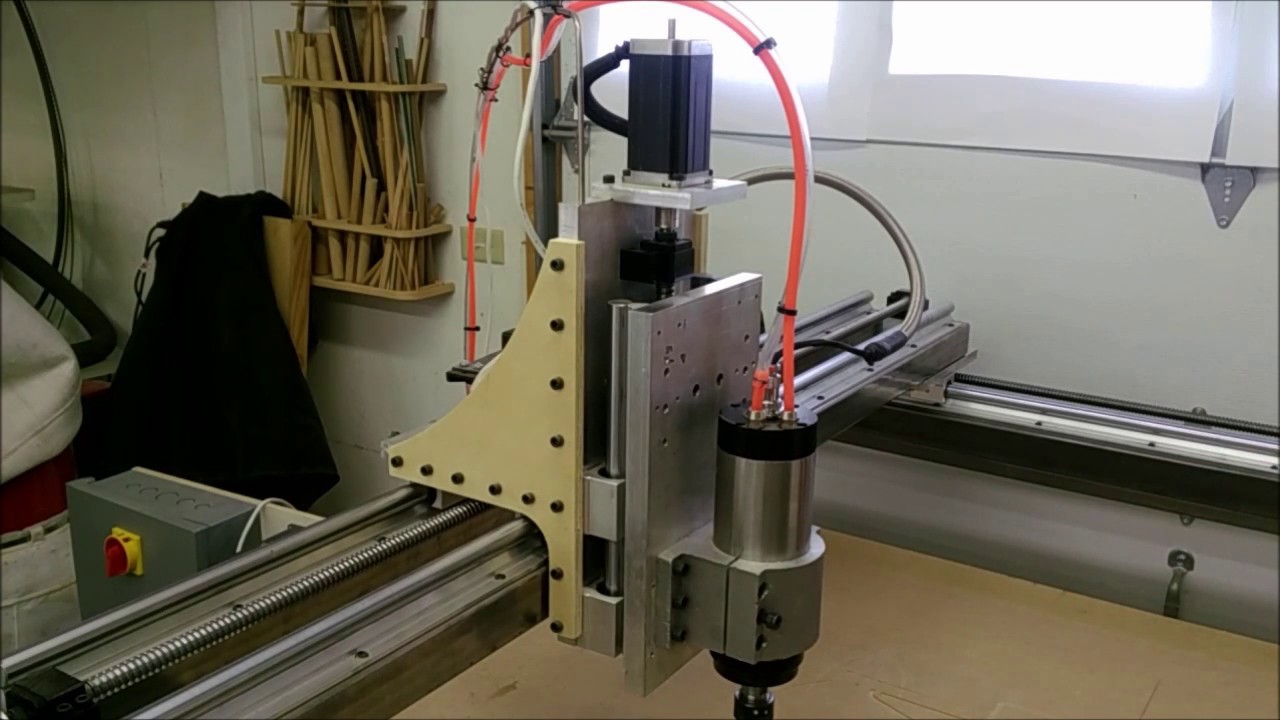

This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

How to build your own cnc wood router. All you need to do is assembl the machine or find someone in your area that can assemble the machine We are building a list of individuals to help assemble in your area. Assembled Option includes the complete CNC Router andor Laser is. Get the step-by-step plans for this Shop-Built CNC Router here.

To provide additional support for the X-axis he set two pieces of tube steel into notches in the front and back of the machine. This is the second DIY CNC Router I made after learning a lot from building the first version. CNC wood router can make many instruments like piano guitar violin and others.

Drill and tap some mounting holes in the edge of each bearing and. 3x 8-32 x 1 ¼ machine screw. This is a very good router that can be built at a reasonable price using readily available materials.

71 Start by attaching one of the timing belt pulleys to the front shaft of the. Nevertheless the key steps to build your own CNC machine will generally be as follows. With a working area of 24x48 you can build this for a lot less than the cost of a similar commercial CNC router.

These plans document all the steps I followed to make my DIY CNC Router. Musical instruments have high requirement on precision and aesthetics. But Ray built the moving-gantry CNC.

I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily. Shipping cost will be provided when parts are ready to be shipped. A CNC machine is probably the most useful tool a hobbyist can own but the price for a CNC machine on the market is way more than the average hobbyist is willing to spend.