How To Grind A Lathe Parting Tool

Lightly touch the tool to the wheel and then swing a round-nose tool Photo A or slide a square-edge one Photo B against the wheel maintaining the end contour.

How to grind a lathe parting tool. I intend mostly to use them for roughing and for preliminary grinding of reliefs on drills. 45 is a good general angle. Turn the parting tool over and do the opposite side for the same amount of time.

Even so this little tool is tempting because grinding a parting tool from a tool blank is a pain - since so much metal must be ground away - and parting tools get dull and break easily. If youve used the bench grinder recently youll want to dress it removing the old bits of debris caught in the stone. To resume grinding re-establish your tool angle and push.

If using an indexable part-off tool check that the cutting insert is in good condition. This video covers how to properly grind the tool how to set the tool so it is ri. Put the tool on center if you put the tip below center you run the real risk of having the part roll over the bit this breaks things.

I was working on a handle for a gouge blade. You can use whatever back rake you like if you achieve it by angling the entire blade like the Aloris holder. You can apply a degree of back rake at the same time too if you desire.

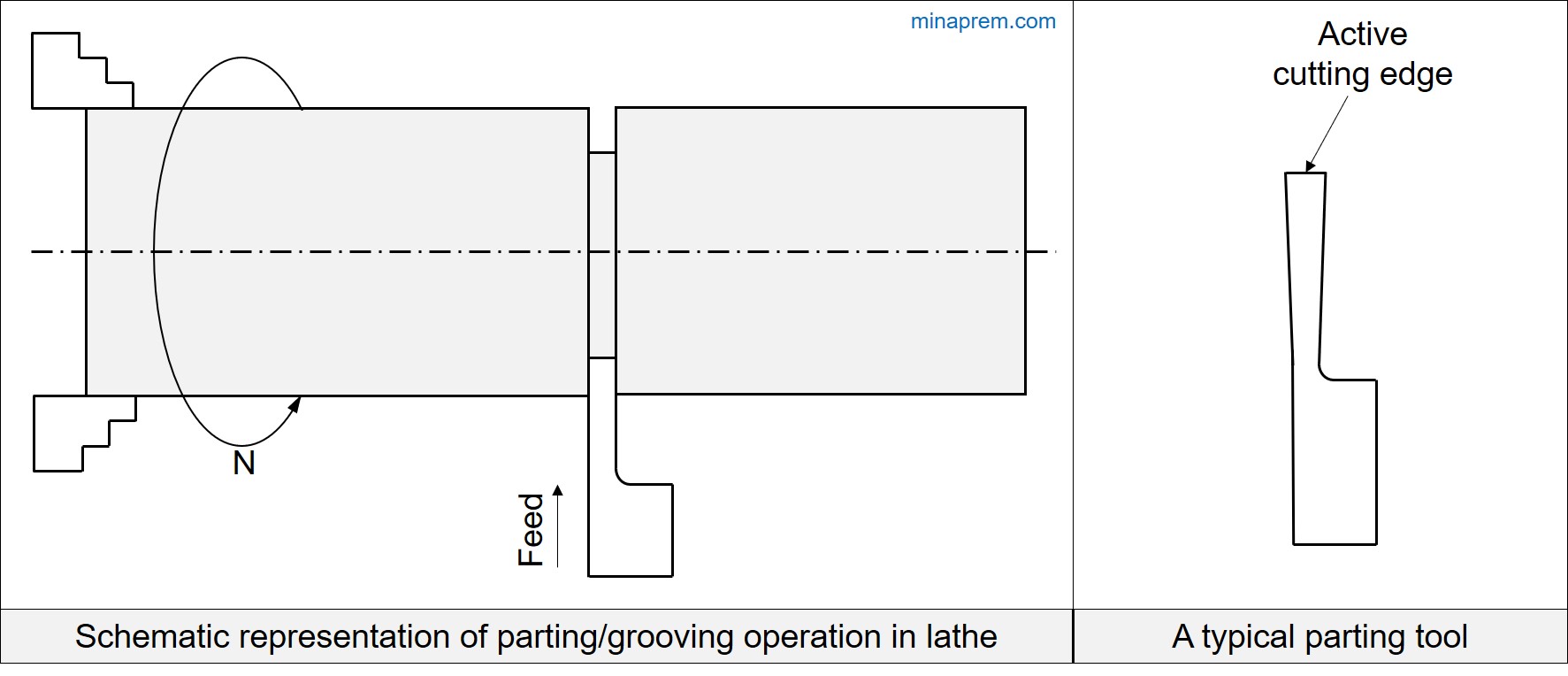

Parting is one of the most misunderstood machining operations on the lathe. To be clear the back rake angle on the P-parallel bits is best controlled by the choice of tool holder. If you break off the end you just grind a.

Being excited I went to the wood lathe to try out the new parting tool. Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. Position the tool rest 10 from horizontal to grind an 80º bevel on the blade.