What Are The Five Safety Precautions Use In Machine Workshop

They must be strictly followed for safety.

What are the five safety precautions use in machine workshop. A guide to machinery and equipment safety is provided to assist persons conducting a business or undertaking PCBU and workers to comply with their duties under the Work Health and Safety Act 2011 the Act and the Work Health and Safety Regulation 2011 the Regulation. Only students on the authorized list are permitted to use the workshop. Always stop machine for cleaning chips and curls.

Safety Precautions can be defined as measures taken in the workshop to avoid accident or harm which one may encounter in the workshop. Shop Safety Checklist Safety Checklist Checklist Safety. Wear shirts or uppers with sleaves cut off or rolled.

FACULTY WORKSHOP SERVICES Safe Use of Machine Shop Equipment Machine Shop Safety August 2014 5 WORKSHOP MACHINES - BAND SAW Ensure the guard doors are closed and the blade is properly adjusted prior to turning on the machine. Adjust the upper guard assembly to within ¼ inch of the stock prior to starting the machine. Never put other things on the milling table while working on the job piece.

Wear clothing suited for the job wear shoes with thick soles. This guide is an introduction to managing the risks associated with use. Wear safety shoes if heavy work is being done.

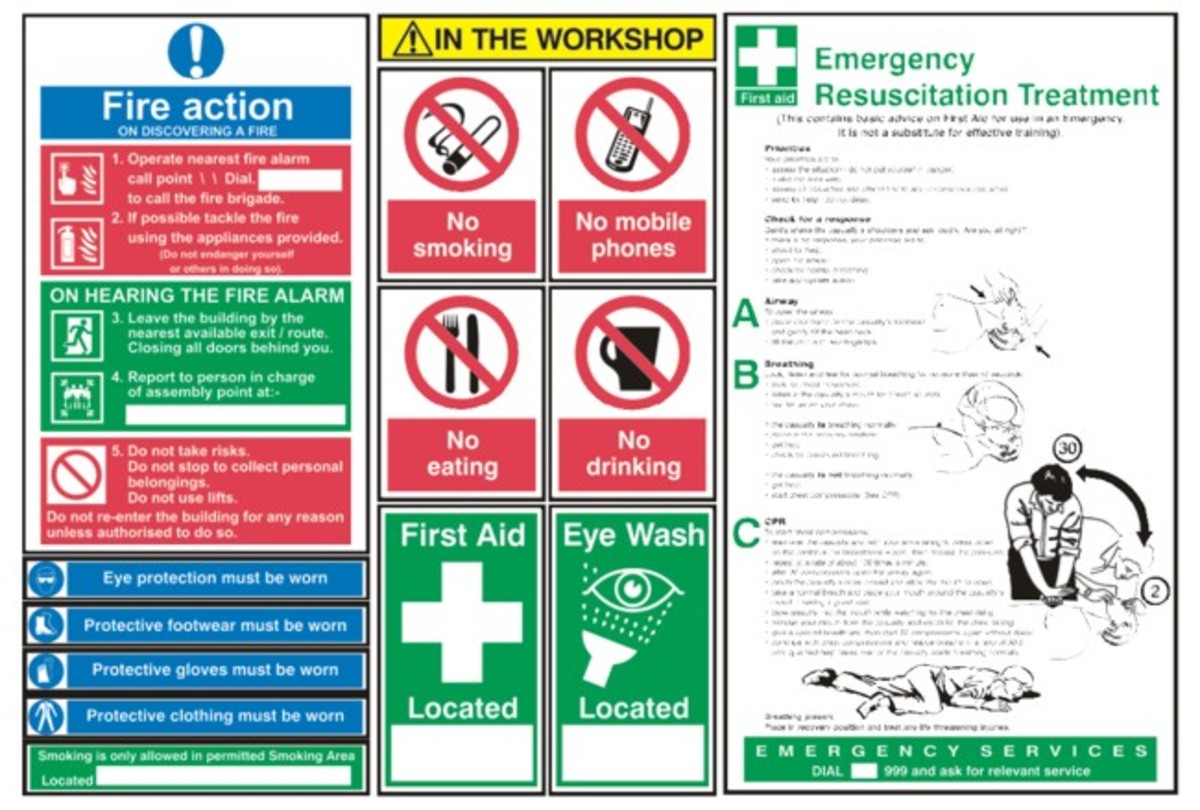

Types of Safety precautions while working in an industry workshop with tools and machines. Always stop the machine for making measurements and adjustments. Machine Safety at Carleton.

Unsuitable clothing Large loose clothing unbuttoned shirt wearing neckties. Safety Precautions Always Wear Approved Safety Glasses Rollup Sleeves Remove Tie And Tuck In Looseclothing Never O Lathe Machine How To Remove Lathe. Use the supplied chip brushes and rags to clean machinery.