What Are The Different Types Of Marking And Measuring Tools Used In Fitting Shop

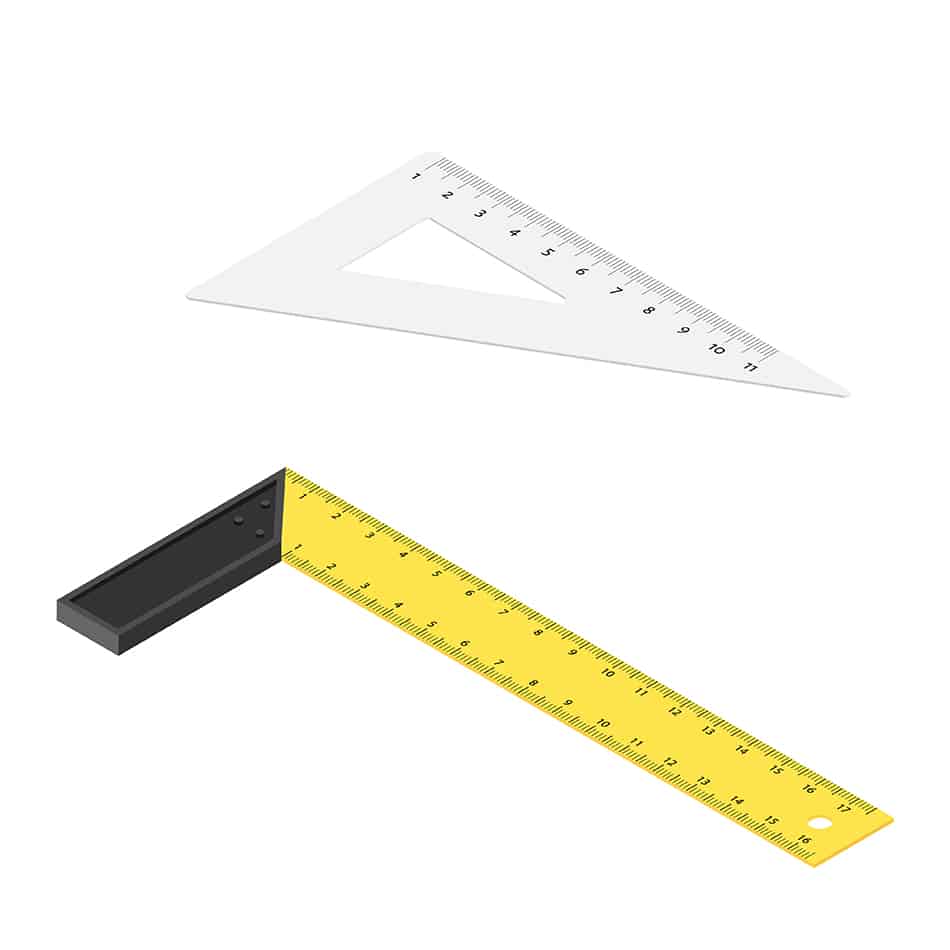

Use of this marking tool or marking out tools in a fitting shop to mark a given angle with an edge or to check the angular precision of oblique surfaces.

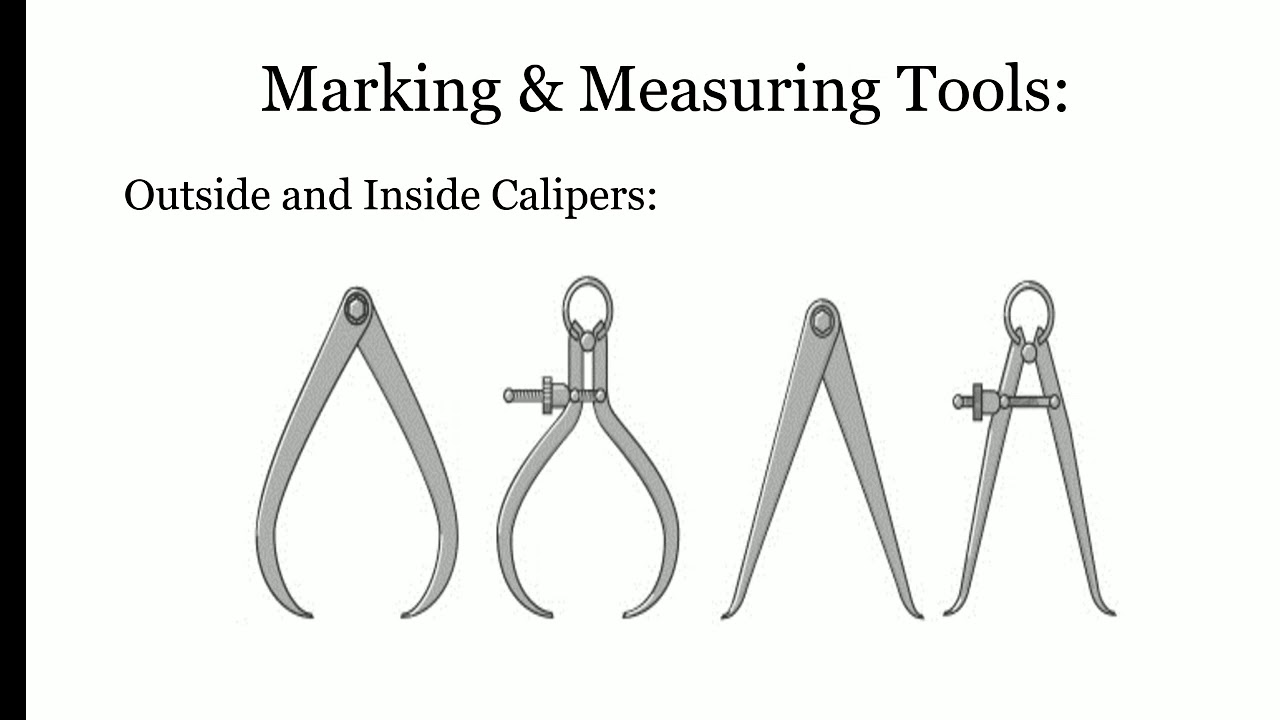

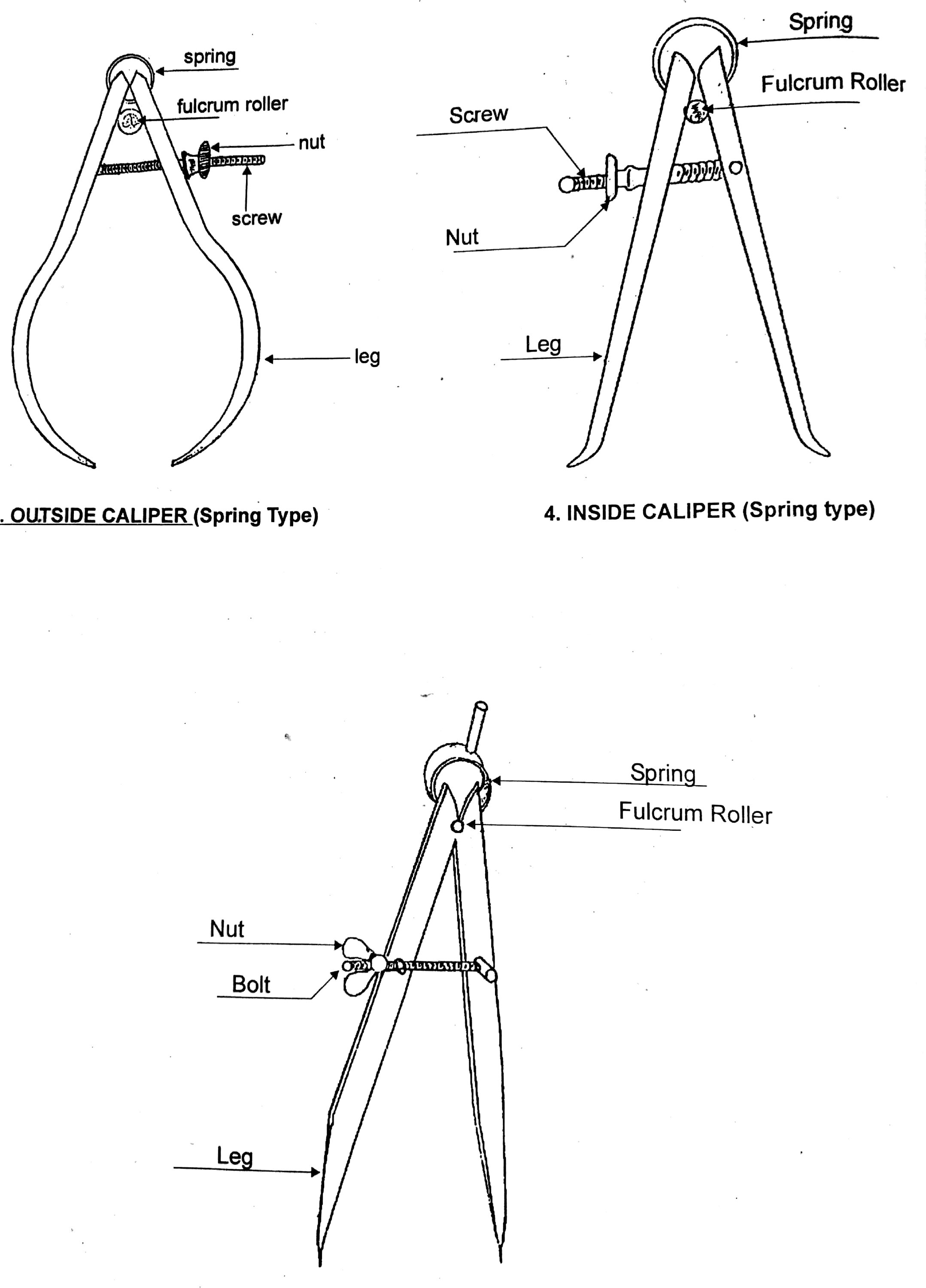

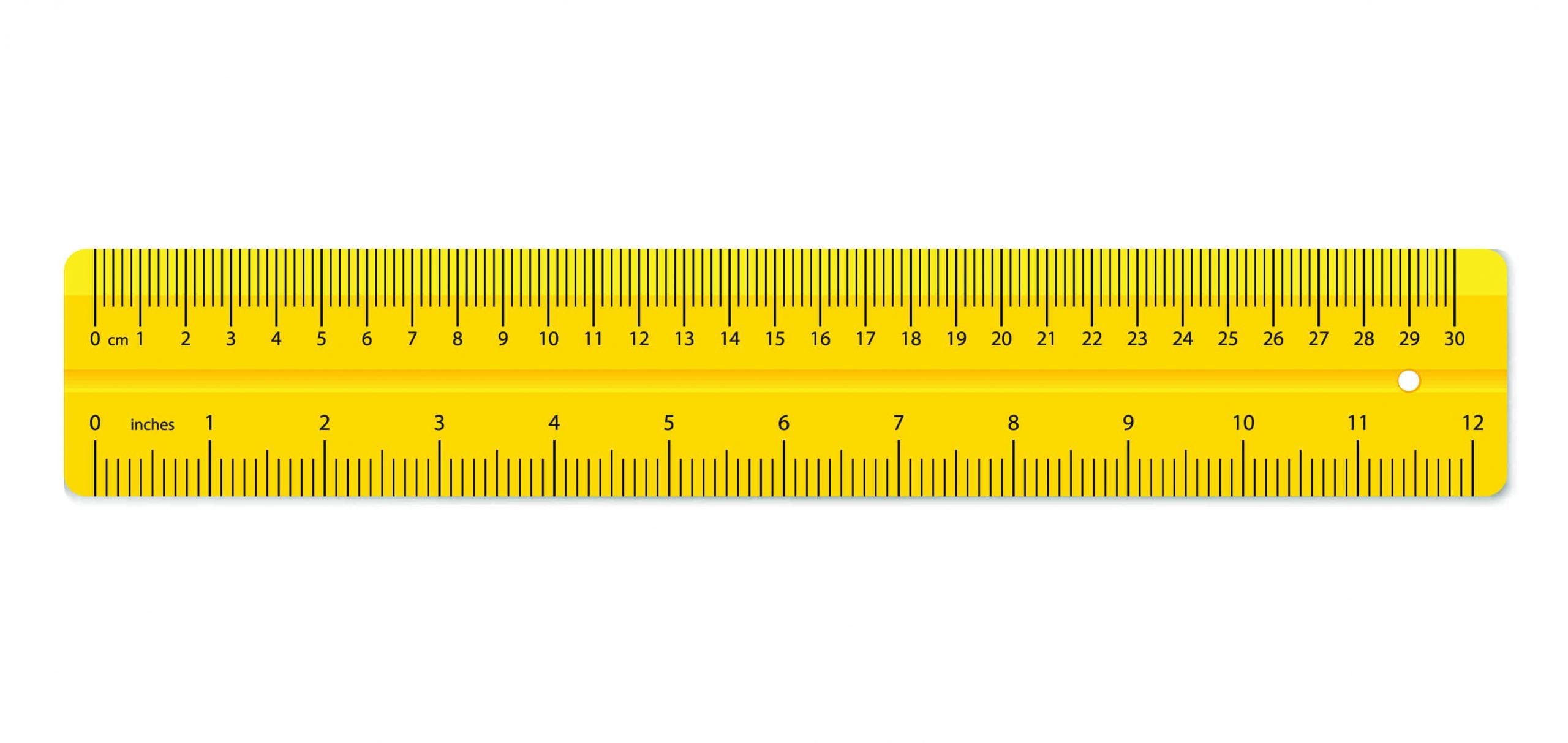

What are the different types of marking and measuring tools used in fitting shop. To finish the work to the desired shape and size. Steel rule. The common tools used for marking out are as follow.

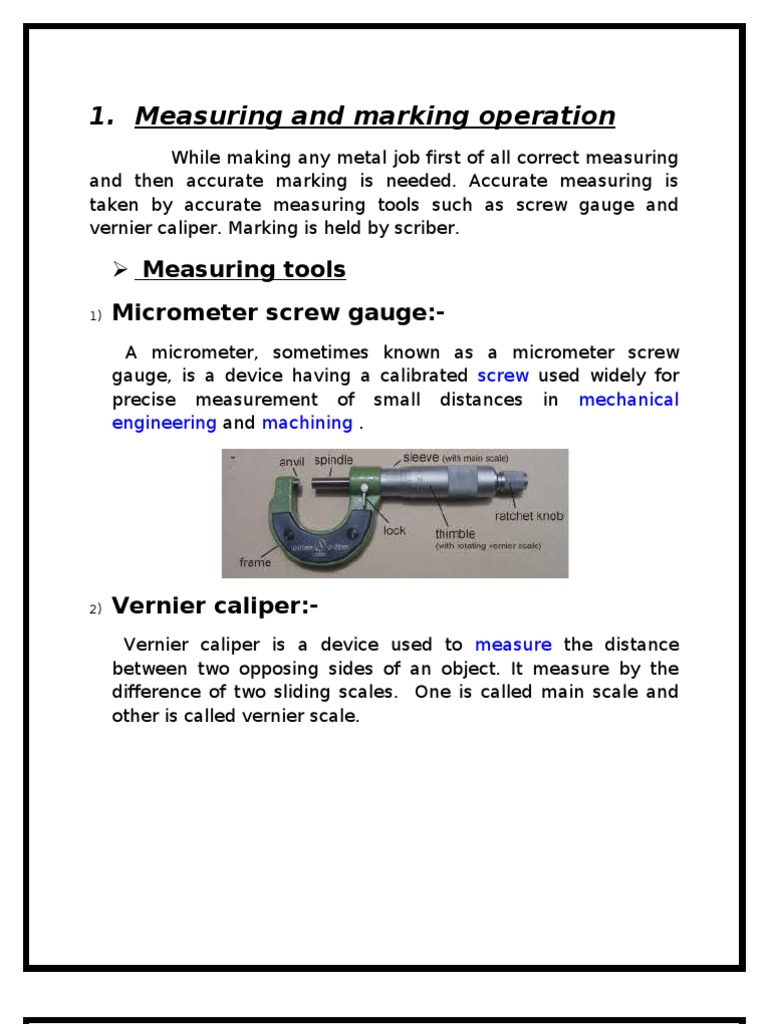

Measuring Tools are used to. Combination Squares are a more modern style of metal square and I find them very useful in my workshop for many tasks. 13 MARKING AND MEASURING TOOLS 131 Surface plate The surface plate is machined to fine limits and is used for testing the flatness of the work piece.

It varies slightly in size but has a blade that can be moved in 360 and locked in a fixed position. The striking tool is identified by a hammer. A number of marking and measuring instruments namely Rules Try Square Combination Set Bevel Gauge Marking Gauge Mortise Gauge Cutting Gauge Spirit Level Trammel and Compass are commonly used for this purpose.

Measuring and inspection of components and maintenance of equipment is also considered as important work of fitting shop technicians. All types of work require the use of large number of tools involving a number of operations such as filing chipping scraping sawing tapping etc. Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting Workshop.

The weight range from 025 kg to 2 kg. It is made of hardened tool steel. It is usually made of carbon steel and parallel ends are grinded.

Scriber A scriber figure 13 is used for scratching lines onto the workpiece. Fitting Shop Practical File. Name of the Tools used in the Fitting shop Measuring and marking instruments.