How To Sharpen Carbide Metal Lathe Tools

With steel you can use 10-20 degrees but never try to use a tool ground for steel on brass.

How to sharpen carbide metal lathe tools. Carbide does not lend itself well to offhand grinding although it can be ground that way. It will grab and possibly rip the stock from the chuck or damage the lathe itself. In this video I explore different aspects a slow speed grinding.

It is a sled which rides atop the SVD-110 Tool. They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with. In particular the angles must be precise for best cutting action.

Trace the end of a machinists square to create the 90 layout on the end between the two points you marked. Positive rake will make your tools free cutting reducing deflection and power requirements. For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools.

Apply layout fluid to the top surface and allow it to try completely. Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner.

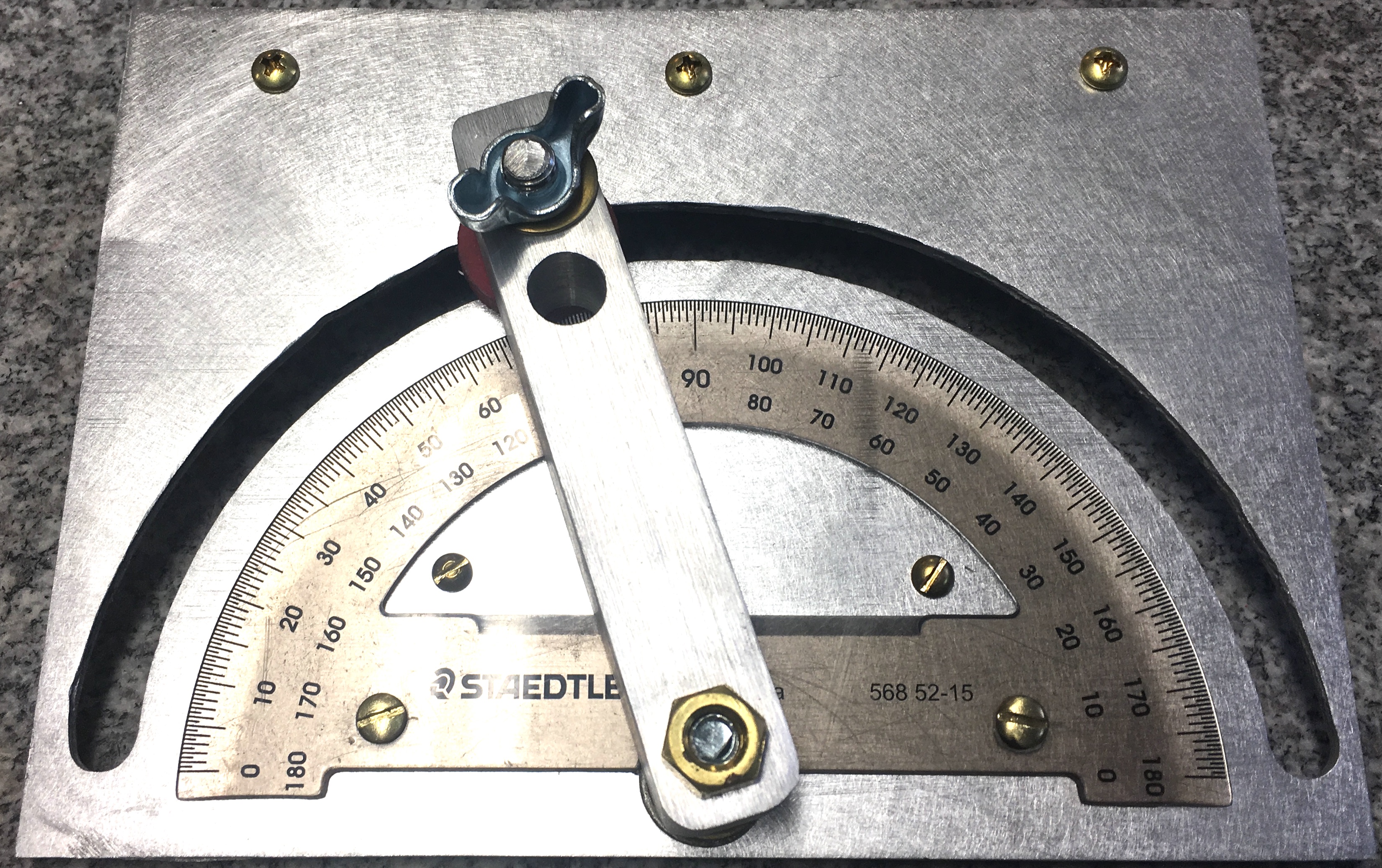

They require a dimond stone because its the only material hard enough to properly sharpen carbide. Shown below is what Ive put together to achieve the level of accuracy desired. Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup.

This video shows how to sharpen carbide cutting bits. How to use a slow speed grinder to sharpen carbide tooling. Lathe tool sharpening is important to making smooth consistent cuts.