How To Program Cnc Wood Router

Then initiate the program.

How to program cnc wood router. Videos you watch may be added to the TVs watch history and. Place your substrate under the drill head and turn on the CNCs vacuum to secure it in place. Woodturning job is symmetrical on both sides we only need to make programming for the left half which is from the central line to the left side.

There are other extensions that will work but these two are the most common. How to make Wooden Gears on a Cnc Router or Mill To make involute gear wheels you do not need an expensive cnc gear cutting program. The computer programming and design that is needed to create the files that are sent to the CNC machine is often referred to as CAD software.

It can cut plates or engrave textures on the surface of item. Allow the router to engrave the substrate. CNC router can achieve a variety of processing effects with high speed and high precision.

But these two methods have certain shortcomings. Whether its a few wooden gears needed to build a mechanical wall clock robot or an anemometer a CAD program can help you create just about any size gear pattern. You need to fix the workpiece onto the machine machine vise spindle or similar work holding device and attach the required tooling end mill drill bit to the machine component.

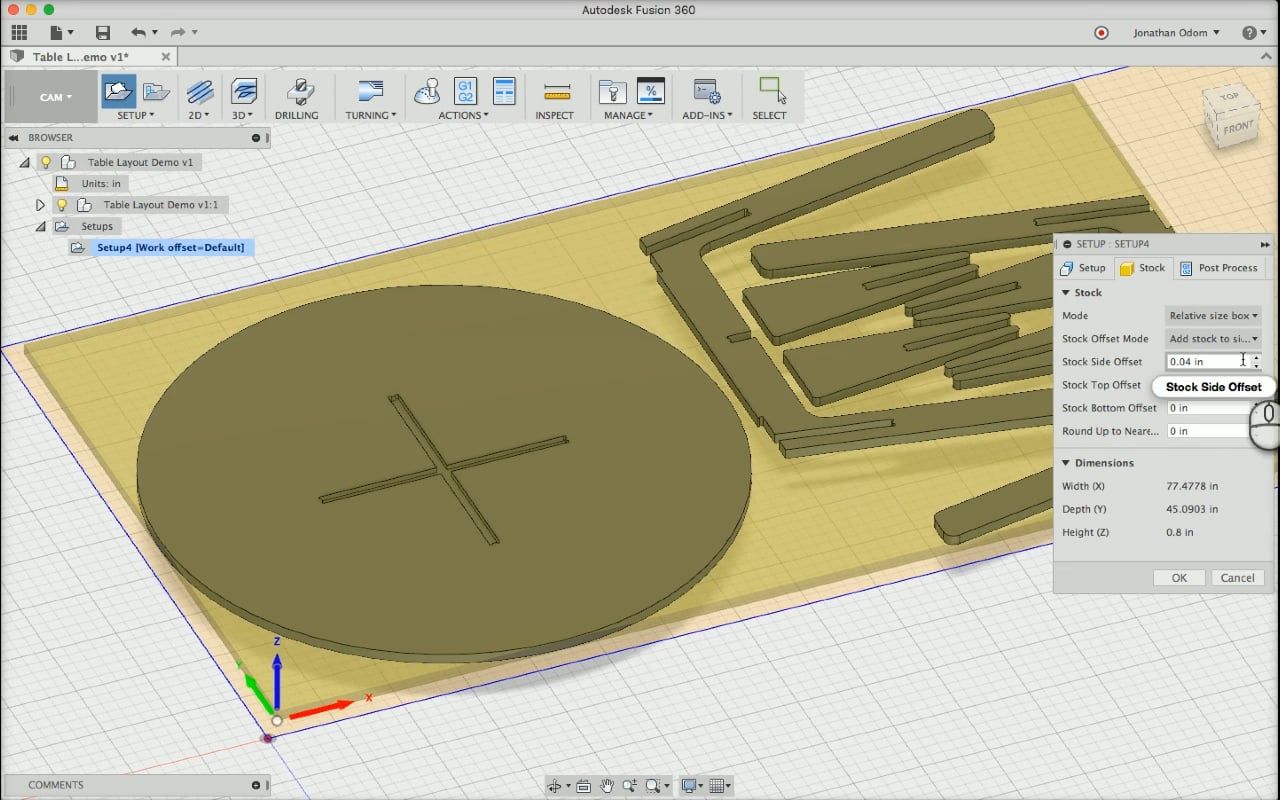

Load the file in your CNC control software and run the program. An advanced CNC wood router can achieve the processing work in a 3D level. The CNC system allows a woodworker to program in the specific cuts he or she wants made then let the machine execute the program.

Other CNC routers may have other types of buttons to signal this command. So our design should be created in the space between the left boundary and the central line. You can create a CNC program in any text editing application.