How To Manage A Cnc Machine Shop

75000 - 85000 a year.

How to manage a cnc machine shop. As you draw up the floor layout its best to involve the. Every person working on a project has his own role and should garner respect from his peers on site. Ive had numerous folks email asking how I price jobs quote jobs etc.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. It may look like a desk job type book but what it teaches fits very nicely with fabrication machine shop work. Where and how are our CAM files post-processors and NC programs to be managed.

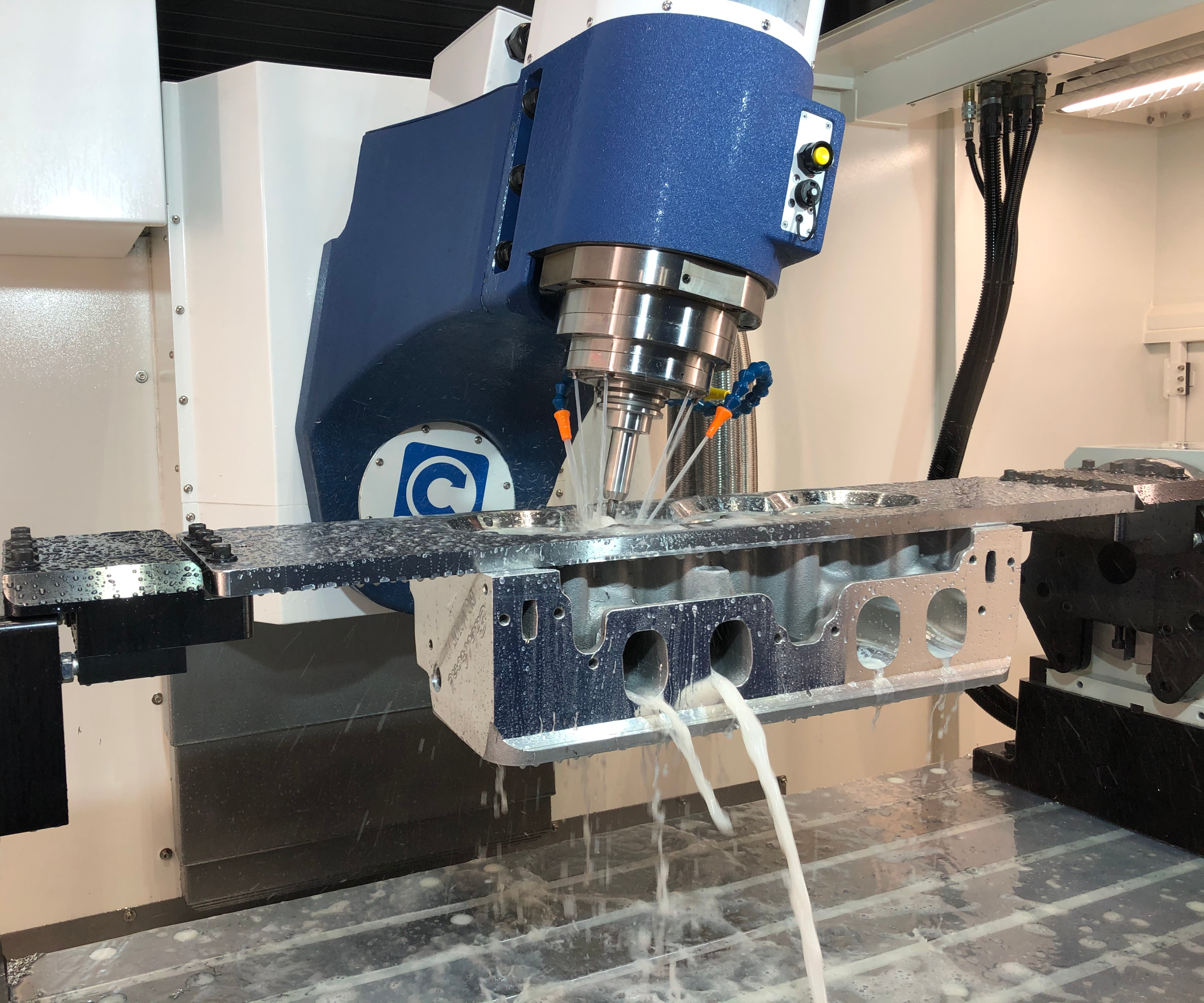

CNC Machining Machine Shop Scraps of wood and metal likely cover the surface of your workshop as proof of how hard you work in that space. Never allow the use of compressed air for cleaning skin and. CNC machine shops.

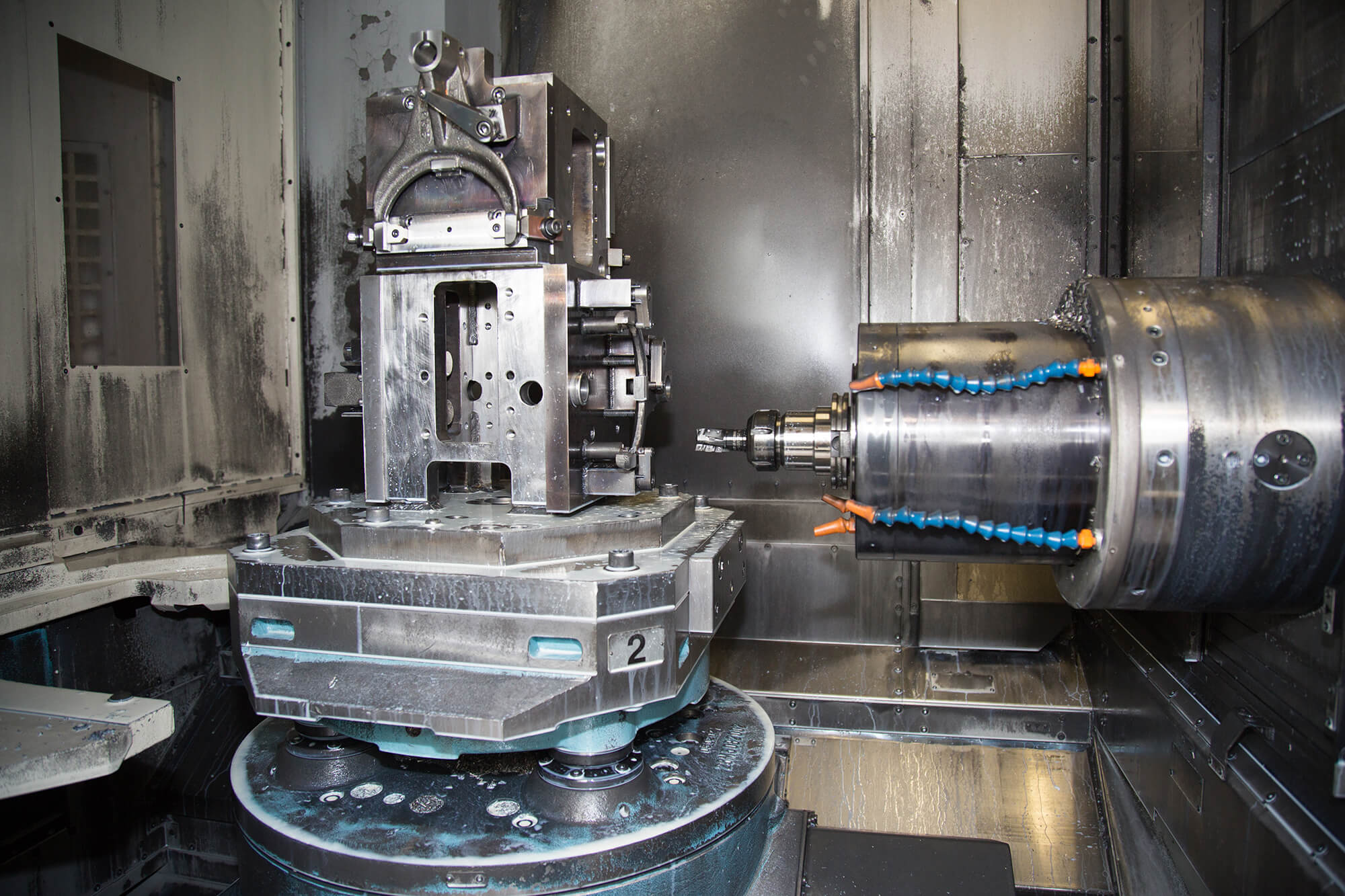

It should go without saying that CNC people directly affect the productivity of the machine or machines on which they work. At the bare minimum the shop owner will need to decide. Keeping the parts tools and production departments of a machine shop.

Try doing an inventory of your staff and see whether youve got all the bases covered youd like to have. Managers Must Understand CNC Responsibilities. Before the advent of the CNC machine shop all machining equipment was operated manually or mechanically which meant that the accuracy of machined parts depended largely on the skill of the machine.

Excellent Benefits and Flexible Schedule. The CNC machine shop is more efficient when all the personnel work together. In machine shops production is critical to revenue.