How To Make Your Own Cnc Wood Router

It would be just like a professional is next to you guiding you every step of the way.

How to make your own cnc wood router. For just a few dollars the student who built this machine was able to make a huge improvement to the look and performance. Learn your unique selling points. Almost every CNC router hobbyist can create this wonderful project without the need for engraving metal parts.

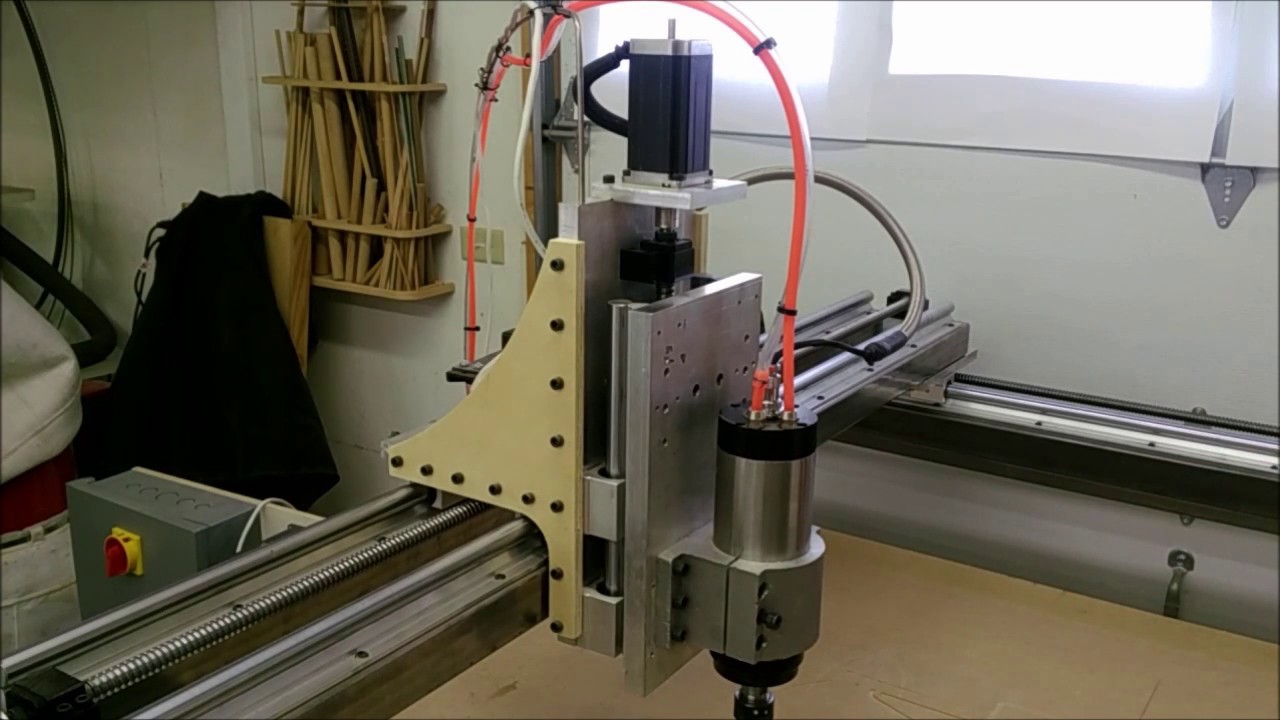

If the machining precision has some gap with the standard it may effect the instruments function. This is the second DIY CNC Router I made after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials.

Building your own 3-Axis CNC router is both fun and educational. Build your own CNC explains how to build program and manufacture your own products on your own machine. CAD Design The first step in the process of cutting something with a CNC is creating a 3-dimensional object of the item you are wanting to cut.

The basic options to drive each axis are. The main thing to note while preparing the digital image is to remain consistent with any adjustments you make. Making musical instruments is also a good way to run your CNC machining business.

This program is a guarantee that in just a couple of hours youll be able to put together your own CNC machine or smart Saw as I like to call it. For homemade CNC routers drive screws are most commonly used. By using calipers dial indicators and a machinist square you will need to measure precisely.

If you are building a 3 axis CNC router you should buy a kit consisting of three sets of linear rails and two linear bearings per rail. And yes you will need to treat all the measurement tools you use with utmost care. The quality of your fittings bearings and other motion hardware is important.