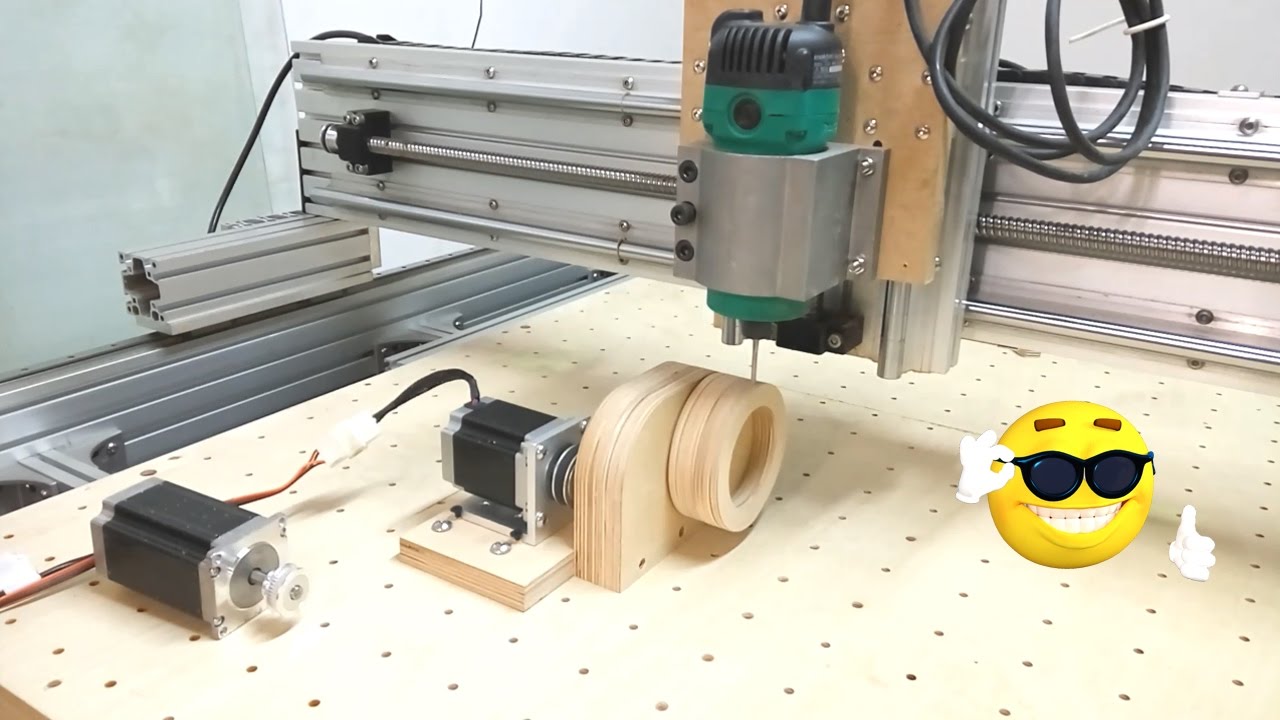

How To Make Lathe Chuck

It is used to hold a.

How to make lathe chuck. Then I will show you how to make this for a fraction of the price. Use light cuts at end about 0010. Now its time to mount your chuck to the lathe after mounting and removing the bowl from the lathe.

Making the four jaw chuck. It is basicly a split Collet. How to make New Lathe chuck keys.

In either configuration if the blank does not seat at the base of the screw chuck it can wobble or work loose and potentially go flying. Carefully cutting out the main part on the bandsaw. Of course if you have a CNC metal lathe the whole.

Once the faceplate is attached to the disks put it on your lathe and turn the disks perfectly round removing as little wood as possible to maximize the size of the chuck. Its pretty straight forward even to do it from plate just takes a while. Now with the bar in the jig tighten the chuck and it should not move.

With the new tray on top of the headstock I needed. In this video I will show you how this lathe chuck works and how well it works in a drill. Backplate has been doing its job of holding the chuck on the lathe for 3 or 4 years without complaint.

Adjust as needed small cuts. The faceplate will be permanent so you need to get one specifically for the Longworth chuck. With it still in lathe check that bar will slide into hole.