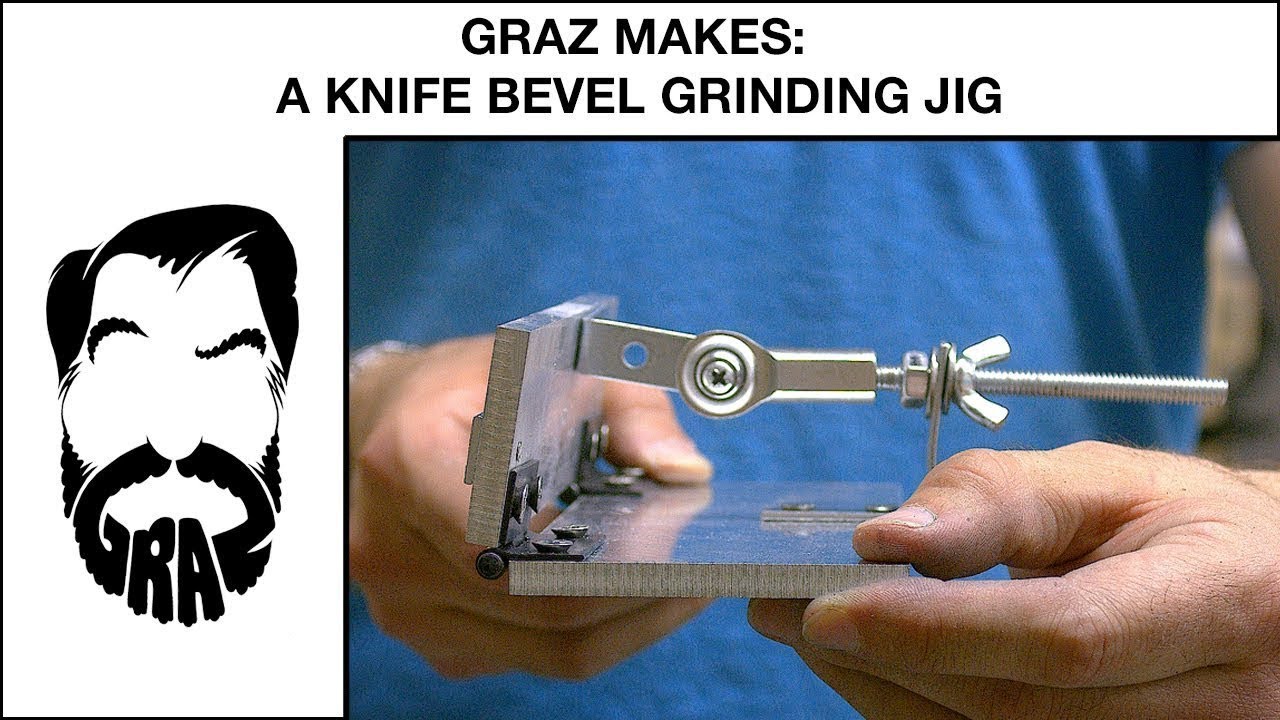

How To Make A Grinding Jig

How To Make A Knife Edge Grinding Jig Simple CheapThis video will show you how to make a simple and cheap jig to grin your edge out on your knives.

How to make a grinding jig. Made of 12 plywood 1. The tighter the better. 38 - 16 x 716 T-Nuts - 2pk.

38 - 16 x 2 SS Socket Cap Screw - 1pk. Before you start grinding make sure you have the centre line or two lines close to centre that mark how thick the blade should be once it is ground scribed onto the cutting edge. This bevel is subsequently refined by honing until a satisfactorily sharp edge is created.

I need to sharpen almost all of my chisels and plane blades so Ive decided to make this simple sharpening jig to streamline and improve the processMore in. The metal widget with the springs is there just to make sure the work rest the piece of cherry with the c-clamp on top doesnt move around and change the distance of the knife to the wheel. Everbilt 45 adjustable spring hinge - 1x.

Try to make parts that are the same at the same time attached together to make both pieces identical to have a straight jig. After receiving some questions I decided to make a tutorial on how to make my grinding jig. I would have made an instructable out of it but I dont have any pictures of the process and its pretty easy to see how the thing goes together any way.

Jig to grind bowl and spindle gougesdif. To grind the convex grind will take some basic math to thin of in advance and calculate the angles and thus the height setting of the bolt to make. These are the parts I bought for the project.

Metal angle bracket sturdy - 1x. To create this cutting edge a bevel is formed on the blade usually by grinding. HelloI made Bench Grinder Tool Sharpening JigThis jig was made for the purpose of tailoring Japanese plane blades but it can be used as a sharpening jig.